Self-drilling screws offer ease and efficiency in the building and construction industry. Their innovative design reduces the need for additional tools, saving you time and money on projects.

Whether you’re an expert or a frequent DIYer, our guide will walk you through the definition of self-drilling screws, their benefits, and a step-by-step on how to use them.

What are Self-Drilling Screws?

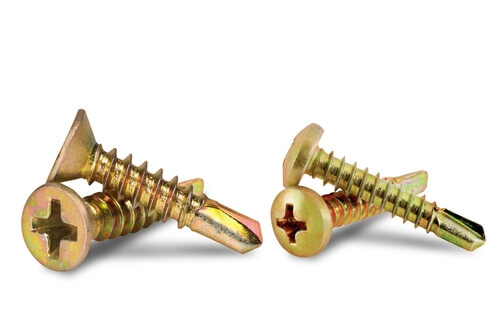

Self-drilling screws are designed to bore, tap, and fasten materials in one single action. They are typically used in metalworking, woodworking, or construction due to their durability and time efficiency.

Their drill-shaped point allows it to penetrate surfaces, similar to a drill bit. This eradicates the need for pre-drilled holes, simplifying the installation process.

These are typically designed with hardened steel and coated with protective finishes such as zinc or anti-corrosion coatings.

The Benefits of Using Self-Drilling Screws

There are various benefits to using self-drilling screws, including:

- Versatile use: They are designed to penetrate a wide range of materials, including wood, plastic, metal, and composites.

- Enhanced security: They create precise threads in the material they penetrate, ensuring a tight fit.

- Cost-effective: Self-drilling screws reduce the need for pre-drilling and tapping tools, helping you save money on projects.

- Durable: Due to their protective coatings, these screws prevent corrosion and rust. This makes them suitable for outdoor or moisture-prone applications.

- Clean appearance: Self-drilling screws offer flush finishes to decorative options, serving various needs and improving aesthetics.

How to Use Self-Drilling Screws

Once you get the hang of it, self-drilling screws and quick and easy to use. Follow the steps below for an efficient installation:

1. Select the Right Screw

There is a wide range of seld-drilling screws on the market designed for various projects.

Choose a fine thread for thinner materials and a coarse thread for thicker or softer materials like wood and plastic. The Phillips drive allows for better control, whilst the Torx drive provides more security. Choose a square drive for resistance and precision.

The popular head types include:

- Flat Head: Sits flush with the surface, creating a smooth finish.

- Pan Head: Has a slightly rounded top for a balance of strength and aesthetics.

- Hex Head: Provides a robust connection, suitable for heavy-duty applications.

- Truss Head: This features a larger head diameter for distributing load, useful for sheet metal.

2. Gather your Tools

Choose a power drill for control with precise tasks or an impact driver for harder materials or large screws.

Then, select the right bit or socket for your screw. For Phillips, Torx, or square-drive screws, ensure the bit fits snugly to avoid stripping the head.

Adjust the torque to a lower setting for softer materials and a higher setting for harder materials.

3. Mark and Position the Screws

Determine where the screws need to go. Mark the positions on the material with a marker as a guide when installing the screws.

If you’re joining two or more pieces, securely clamp them together before drilling to prevent shifting.

4. Drilling and Fastening

Position the drill or impact driver so that the bit or screw is aligned with your marked position.

Then, apply pressure in line with the screw to allow it to pierce into the material. Once it has started to penetrate the surface, gradually increase the speed so that the self-drilling tip creates a hole. The threads will then start to catch.

Ensure the screw remains straight. For flush or countersunk applications, stop driving when the screw head sits level with or slightly below the surface. As the screw reaches its final depth, reduce the speed and check the fastening.

Choose ASP for Self-Drilling Screws!

We hope that our guide has helped you successfully install your self-drilling screws.

If you’ve not yet started on your project, our self-drilling screws will ensure a clean and efficient job. With options including hardened steel, stainless steel, and bimetallic, we have a screw for every application.

Or you can browse our wide range of screws today for every professional and DIY job.